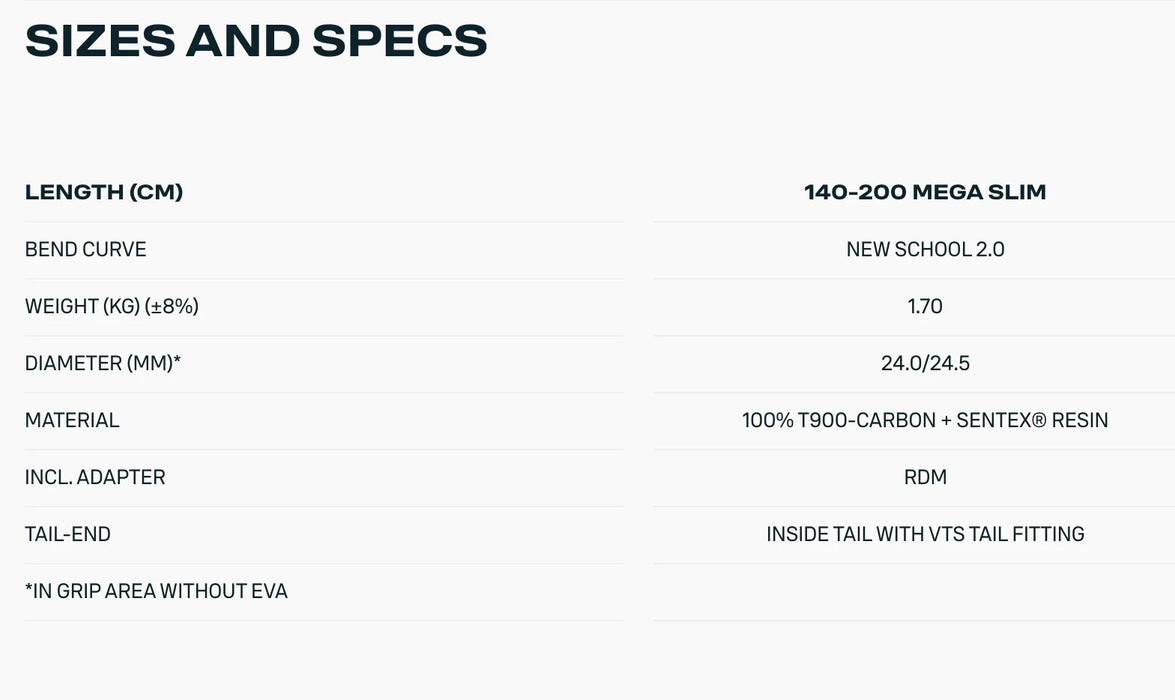

Duotone Platinum Aero 3 Carbon windsurfing boom 140-200cm

Duotone Platinum Aero 3 Carbon windsurfing boom 140-200cm, one of the lightest and stiffest booms available.

Thanks to the highest-quality mix of materials and unique production methods, it is an astonishing 200-400 g lighter than the already ultra-light PLATINUM SLS counterpart. Despite its slimmed-down weight, the PLATINUM AERO 3.0 is identical in design to the PLATINUM SLS SERIES.

With nearly 3 decades of Maui development and Munich engineering, DUOTONE has the most incredible experience in carbon booms in the industry.

The new PLATINUM AERO 3.0 lineup underscores this by being the most feature-packed carbon booms available. The goal was to create the highest-performing booms, combined with the best ergonomics, unmatched stiffness, and the fastest operation. Here comes a rundown of these feature monsters:

FULL CUSTOM CONSTRUCTION We use 100% highest-grade T900 prepreg carbon and our exclusive SENTEX® resin impregnated with silicon nano-spheres.

SEGMENTED CROSS-SECTION TECHNOLOGY This results in a quantum leap in weight >< stiffness >< grip-ergonomics/comfort. With weights of 1.70 and 2.70 kg (depending on the length), the PLATINUM AERO 3.0 are the lightest booms on earth. The secret of these super-light weights lies in the SEGMENTED CROSS-SECTION TECHNOLOGY. Instead of the usual round cross section, the PLATINUM AERO 3.0 feature a super sophisticated transition of different cross sections:

- The SQUARE FRONT SECTION, featuring a massive wall thickness, increases the stiffness by approximately. 30%

- The OVAL TAIL SECTION increases the lateral stiffness by another 30%

This results in the new PLATINUM AERO 3.0 not just being the lightest but also one of the stiffest booms. Another advantage of the OVAL TAIL SECTION is the reduced tail weight. Due to the leverage effect, this has a tremendous impact on how light the PLATINUM AERO 3.0 feels in your hands (= sailing weight).

GRIPPING DIAMETER: GRIP COMFORT VS. STIFFNESS With the diameter in the gripping area, you are dealing with two contradictory facts:

- The thinner the diameter, the more comfortable and less tiring it is to hold on to

- The thinner the diameter, the softer the boom becomes

The enormous stiffness generated in the front and back allowed the use of smaller diameters than any other boom in the gripping area. Together with the OVAL INSIDE GRIP SECTION, this leads to an unmatched gripping comfort and reduced fatigue - sail longer and no more cramped forearms!

60 CM EXTENSION RANGE ON ALL BOOMS

- Just one boom to cover all your Wave sails

- Just two booms covering all racing disciplines and sizes

DISCIPLINE-SPECIFIC BEND-CURVES All our bend-curves are designed to allow your front and back arms to sit in a natural ergonomic position while sailing. This position varies with the type of sail (Wave >< Race), so each boom size needs to be developed accordingly.

- The 140 Mega Slim has received a completely new bend curve called NEW SCHOOL 2.0. For the first time, it combines the advantages of a straight new school curve (no overstretching of the front hand) and a performance-oriented curve (wider distance of the tubes in the centre to avoid the sail profile from getting distorted).

- For the 190, we use the same tried-and-tested race curves that have proven themselves in countless race victories over the last decade.

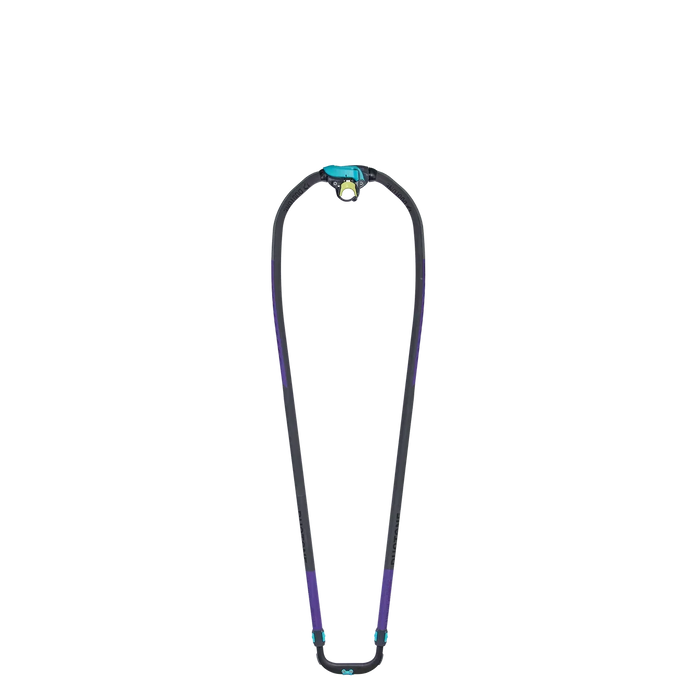

iFRONT 2.0 The lightest moulded front-end on earth

PROTECTION GRIP INSERTHigh-densityy EVA grip inserts on the outside front arch for maximum abrasion resistance during rigging

EXTERNAL TAIL FITTINGS External tail fittings provide three main advantages compared to integrated fittings:

- Lower weight

- Stronger tail end. No weak points in the mould

- Exchangeable

INDIVIDUAL TAIL FITTINGS

- The 140 size comes with our patented VTS TAIL fitting, which visually indicates the correct outhaul tension (DUOTONE sail required)

- The 190 size comes with the iTAIL RACE fitting, which allows loop-loop-go (the fastest way to rig your outhaul) even when used with an adjustable outhaul system.

TRIANGLE BEARING CONSTRUCTION Bearings in between the rotational front-end and the monocoque carbon body prevent the front-end from „grinding down“ the carbon, which ultimately leads to a broken boom.